Discover the Virtuosity of In-Mold Decorations in Production

Discover the Virtuosity of In-Mold Decorations in Production

Blog Article

Understanding In-Mold Decorations: Techniques, Patterns, and Ideal Practices for Optimum Outcomes

In the world of production, the art of in-mold decorations stands as a critical aspect of item layout and production. As industries consistently look for cutting-edge means to improve aesthetic allure and performance, mastering the details of in-mold decorations has become an important skill set. From choosing the ideal products to including innovative style trends, the journey in the direction of achieving optimal cause this domain name is complex. By delving into the methods, patterns, and best practices that underpin successful in-mold decoration procedures, companies can open a world of possibilities that not only raise the aesthetic allure of their products however likewise simplify production performance and strengthen customer involvement.

Material Option

Product option is an essential facet of grasping in-mold designs, as it directly affects the top quality and durability of the end product. When choosing products for in-mold designs, it is vital to take into consideration variables such as compatibility with the molding process, the desired visual outcome, and the environmental problems the item will certainly deal with. Thermoplastic materials like polypropylene, abs, and polycarbonate are generally used for in-mold designs because of their adaptability and capacity to attain complex styles. These products provide superb moldability, making it possible for makers to produce intricate shapes and patterns with accuracy.

In addition, products with high warmth resistance are favored for in-mold designs, especially for products that will certainly be exposed to raised temperature levels during their lifecycle. By meticulously picking the suitable material for in-mold decorations, producers can improve the total quality and resilience of their items, satisfying the assumptions of both customers and end-users - In-Mold Decorations.

Design Development

A vital consider advancing the area of in-mold decors is the continual exploration and implementation of design innovation methods. Style technology plays a crucial duty in improving the aesthetic allure, functionality, and general high quality of items manufactured making use of in-mold decor procedures. By incorporating innovative style components, suppliers can separate their products in the marketplace, attract consumers, and stay in advance of competitors.

One of the crucial aspects of design development in in-mold decors is the combination of intricate patterns, appearances, and graphics that were formerly testing to achieve with conventional decor methods. Advanced innovations such as 3D printing and electronic design devices enable designers to develop complicated and detailed designs that can be flawlessly moved onto shaped components. In addition, making use of lively shades, metal coatings, and unique impacts like gloss or matte textures can further raise the visual charm of in-mold embellished items.

Furthermore, style technology prolongs beyond appearances to include practical improvements such as ergonomic forms, incorporated features, and adjustable aspects that cater to specific user needs. By accepting layout development, producers can open brand-new opportunities for item, imagination, and personalization distinction in the affordable landscape of in-mold decorations.

Manufacturing Performance

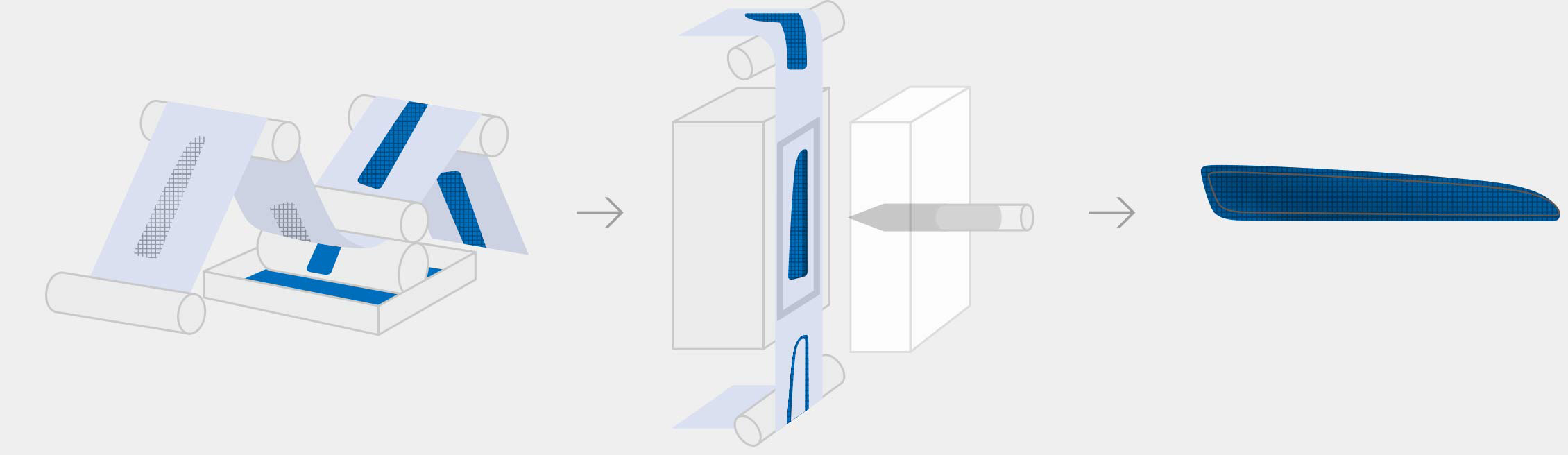

Reliable manufacturing processes are crucial for equating the cutting-edge styles created in the field of in-mold decors right into high-quality ended up products that fulfill market demands and consumer expectations. In the world of in-mold decors, production effectiveness includes various essential facets that add to the overall success of the manufacturing process. One critical component is the important source optimization of mold design and tooling to guarantee specific and smooth decor transfer onto the final item. By fine-tuning mold arrangements and purchasing high-grade tooling products, suppliers can improve performance and uniformity in manufacturing.

Automation not just accelerates the manufacturing procedure but also enhances precision and repeatability, leading to an extra high-grade and uniform end product. Generally, an alternative approach to manufacturing efficiency is critical in optimizing the capacity of in-mold design strategies and accomplishing optimal results in the affordable market landscape.

Top Quality Control Steps

What are the key methods for making sure rigorous high quality control measures in the realm of in-mold decorations? Quality control actions are vital in in-mold decoration processes to make sure the manufacturing of remarkable and high-grade finished products.

Making use of sophisticated modern technologies such as automatic evaluation systems can additionally boost the top quality control process by giving trustworthy and accurate information for evaluation. These systems can discover flaws that might be missed by hand-operated evaluations, therefore boosting total product high quality and uniformity.

Normal training and growth programs for workers associated with the in-mold design process can also contribute to maintaining premium requirements. By informing team on best methods, top quality expectations, and the relevance of focus to detail, companies can cultivate a society of top quality awareness throughout the organization.

Customer Appeal

To enhance the bankability of in-mold design items, comprehending and providing to consumer choices play a crucial duty in establishing their charm and success. Consumer allure in in-mold decorations is affected by different aspects, including layout visual appeals, color selections, longevity, and overall functionality. Consumers are progressively seeking personalized and one-of-a-kind items that reflect their individuality and design. Therefore, providing personalization options such as tailored layouts, color variants, and textural aspects can considerably improve the allure of in-mold design items.

Verdict

In-mold decors supply a efficient and functional means to boost item appearances. By official statement meticulously choosing materials, embracing innovative styles, enhancing production procedures, implementing quality control actions, and prioritizing customer appeal, producers can accomplish optimum outcomes. It is essential for firms to continually adjust and enhance their strategies to remain affordable on the market. In-Mold Decorations. Grasping in-mold decors requires a holistic strategy that thinks about all facets of the manufacturing process to ensure success.

In the realm of production, the art of in-mold designs stands as an essential aspect of item design and manufacturing. Style technology plays an essential role in improving the visual allure, capability, and overall high quality of items produced utilizing in-mold design procedures.One of the crucial facets of design innovation in in-mold designs is the integration of complex patterns, appearances, and graphics that were previously testing to accomplish with conventional decoration methods.Reliable manufacturing procedures are important for translating the innovative styles established in the field of in-mold decorations right into high-grade ended up items that fulfill market demands and customer expectations. Providing modification options such as tailored styles, color variations, and textural aspects can significantly improve the allure of in-mold decor items.

Report this page